Industrial Adhesives and Lubricants

Industry relies on Lubricants and Adhesives for every day maintenance and production.

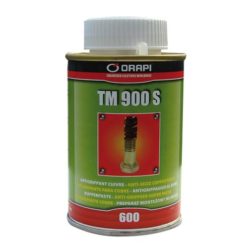

We chose Orapi for their world leading product range manufactured in Europe that is second to none.

Every product is clearly labeled with application information and vital technical details.

We offer a comprehensive range from stock but other products are available from the distribution centre if required.

Showing 1–24 of 28 results

-

Orapi EL0115 Versatile High Performance Lubricant

-

Orapi 953 Belt Adherent

-

Orapi 810 Codex Mineral Oil

-

Orapi 806 Synthetic and Clean Lubricant

-

Orapi 805 Water Repellent

-

Orapi 800 Super Anti-Seize Agent

-

Orapi 799 Lubricating and anti-seize agent

-

Orapi 705 Teflon based Synthetic Lubricant

-

Orapi 620 Silicone Grease

-

Orapi 618 Teflon Grease

-

Orapi 615 Grease

-

Orapi 609 Universal Grease

-

Orapi 608 Lithium Soap

-

Orapi 606 Semi-Synthetic Grease

-

Orapi 605 Marine Grease

-

Orapi 602 Lithium Grease

-

Orapi 600 Copper Paste

-

Orapi 503 Kleaner

-

Orapi 403 Gasket Seal

-

Orapi 210 Epoxy Resin

-

Orapi 202 Epoxy Adhesive

-

Orapi 307 Bearing Fit

-

Orapi 303 High Strength Retainer

-

Orapi 205 Pipe Seal Teflon